Case Studies

Action Mining Services

Problem

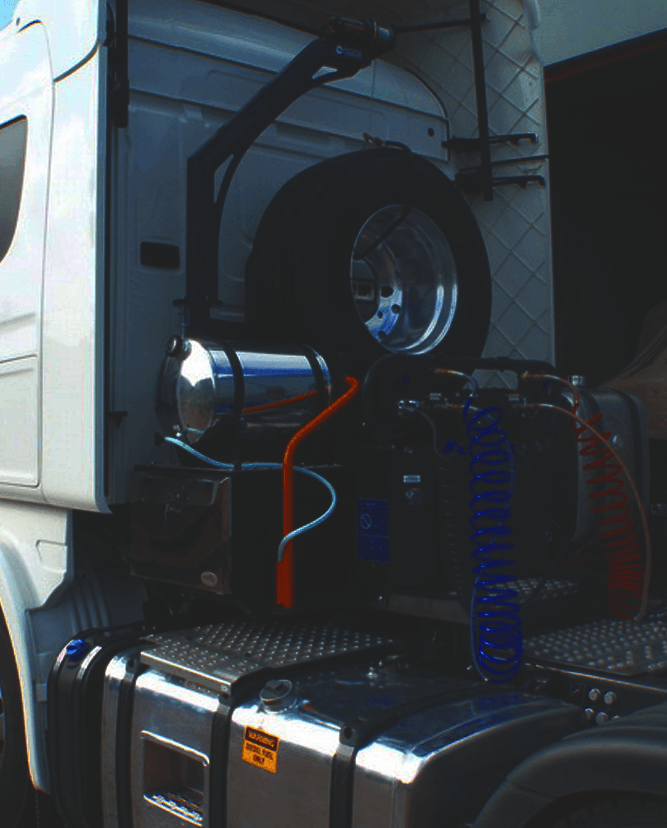

ROPS was approached by Action Mining Services (AMS) to offer advice and possible solutions with regards to the mounting of a single spare wheel to the rear enclosed section of a newly designed service body. During initial discussions with AMS several issues were identified which were required to be overcome to achieve the final goal of a “fit for purpose” solution.

Issues identified included:

- Not enough room to mount a spare tyre in the traditional manner within the existing design of the vehicle body.

- Height from ground level of the spare wheel when mounted in proposed position.

- Operator safety when removing/replacing spare wheel.

- Possible redesign and modification of ROPS existing electric/hydraulic dual spare wheel carrier to suit AMS requirements.

Solution

- Held meetings between ROPS and AMS to discuss all identified issues and possible solutions.

- Reached decision on redesign of existing ROPS product to address all identified issues.

- Fully dimensioned drafting of redesigned product produced for AMS by ROPS for revisions and final approval.

- AMS approved design was manufactured and fitted to vehicle body as required.

Outcome

- All AMS concerns and issues were addressed and resolved to AMS approval and satisfaction.

- “Fit for purpose" product supplied, fitted and commissioned by ROPS in conjunction with AMS.

- AMS was happy with the final product and results, the handling of the scope of work by ROPS and custom solution offered.